Discover 'What is MDF?': An Example from ARTC Solution's Help Center

What is MDF?

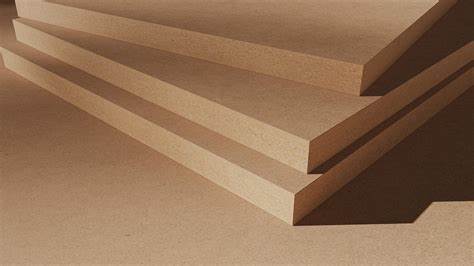

Medium Density Fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining them with wax and resin binder, and forming panels by applying high temperature and pressure. This process creates a dense, flat, and smooth panel that has become a staple in various industries.

Medium Density Fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining them with wax and resin binder, and forming panels by applying high temperature and pressure. This process creates a dense, flat, and smooth panel that has become a staple in various industries.

Characteristics

Smooth Surface

MDF boasts a uniform and smooth surface, which makes it ideal for painting and veneering. Unlike natural wood, MDF doesn’t have knots or grains that can interfere with its appearance and finish.

MDF boasts a uniform and smooth surface, which makes it ideal for painting and veneering. Unlike natural wood, MDF doesn’t have knots or grains that can interfere with its appearance and finish.

Density and Strength

MDF is denser and stronger than particle board but lighter and easier to work with than hardwood. This balance of density and strength makes it a versatile material suitable for numerous applications.

MDF is denser and stronger than particle board but lighter and easier to work with than hardwood. This balance of density and strength makes it a versatile material suitable for numerous applications.

Cost-Effectiveness

One of the significant advantages of MDF is its cost-effectiveness. It is generally more affordable than solid wood or plywood, making it an attractive option for budget-conscious projects without compromising on quality.

One of the significant advantages of MDF is its cost-effectiveness. It is generally more affordable than solid wood or plywood, making it an attractive option for budget-conscious projects without compromising on quality.

Versatility

MDF can be easily cut, drilled, machined, and filed without splintering or chipping. Its fine particles allow for precise and intricate designs, which is why it’s a favorite among furniture makers and DIY enthusiasts.

MDF can be easily cut, drilled, machined, and filed without splintering or chipping. Its fine particles allow for precise and intricate designs, which is why it’s a favorite among furniture makers and DIY enthusiasts.

Manufacturing Process

The manufacturing of MDF involves several steps:

Breaking Down Wood Residuals: Hardwood or softwood residuals are broken down into fine wood fibers.

Adding Wax and Resin: These fibers are combined with wax and a resin binder to provide structure and adhesion.

Forming Panels: The mixture is formed into panels under high temperature and pressure, resulting in a dense and smooth board.

Finishing: Panels are sanded and trimmed to ensure uniform thickness and smooth surfaces.

The manufacturing of MDF involves several steps:

Breaking Down Wood Residuals: Hardwood or softwood residuals are broken down into fine wood fibers.

Adding Wax and Resin: These fibers are combined with wax and a resin binder to provide structure and adhesion.

Forming Panels: The mixture is formed into panels under high temperature and pressure, resulting in a dense and smooth board.

Finishing: Panels are sanded and trimmed to ensure uniform thickness and smooth surfaces.

Applications

Furniture

MDF is commonly used in making furniture such as cabinets, shelves, tables, and beds. Its smooth surface is perfect for painting, and it can be laminated to mimic the appearance of real wood.

MDF is commonly used in making furniture such as cabinets, shelves, tables, and beds. Its smooth surface is perfect for painting, and it can be laminated to mimic the appearance of real wood.

Doors and Panels

Ideal for interior doors and decorative wall panels, MDF provides a smooth, uniform surface that’s easy to finish. It’s also used in the construction of cabinet doors and drawer fronts.

Ideal for interior doors and decorative wall panels, MDF provides a smooth, uniform surface that’s easy to finish. It’s also used in the construction of cabinet doors and drawer fronts.

Moldings and Trim

MDF is widely used for baseboards, crown moldings, and window and door casings. Its uniformity and smooth finish make it an excellent choice for these applications, allowing for easy painting and staining.

MDF is widely used for baseboards, crown moldings, and window and door casings. Its uniformity and smooth finish make it an excellent choice for these applications, allowing for easy painting and staining.

Crafts and DIY Projects

Popular in hobbyist and DIY communities, MDF is used for various projects such as model building, custom shelving, and decorative items. Its ease of machining and affordability make it a go-to material for creative endeavors.

Popular in hobbyist and DIY communities, MDF is used for various projects such as model building, custom shelving, and decorative items. Its ease of machining and affordability make it a go-to material for creative endeavors.

Pros and Cons

Pros:

Smooth Surface for Painting: MDF takes paint well and provides a flawless finish.

Uniformity in Structure and Size: Unlike natural wood, MDF has no knots or grain patterns.

Easy to Machine and Shape: It can be cut, drilled, and shaped without splintering.

Cost-Effective Compared to Solid Wood: Offers a budget-friendly alternative to hardwood.

Smooth Surface for Painting: MDF takes paint well and provides a flawless finish.

Uniformity in Structure and Size: Unlike natural wood, MDF has no knots or grain patterns.

Easy to Machine and Shape: It can be cut, drilled, and shaped without splintering.

Cost-Effective Compared to Solid Wood: Offers a budget-friendly alternative to hardwood.

Cons:

Susceptible to Moisture and Swelling: MDF can absorb water, leading to swelling and warping.

Heavier than Plywood: Its density makes it heavier and more challenging to handle.

Less Strength Compared to Solid Wood: While strong, MDF doesn’t match the structural integrity of solid wood.

Can Emit Formaldehyde: If not sealed properly, MDF can release formaldehyde, which is a concern for indoor air quality.

Susceptible to Moisture and Swelling: MDF can absorb water, leading to swelling and warping.

Heavier than Plywood: Its density makes it heavier and more challenging to handle.

Less Strength Compared to Solid Wood: While strong, MDF doesn’t match the structural integrity of solid wood.

Can Emit Formaldehyde: If not sealed properly, MDF can release formaldehyde, which is a concern for indoor air quality.

Maintenance and Care

Keep Dry

Avoid exposure to water or high humidity to prevent swelling and warping. MDF is best used in indoor applications where it’s protected from moisture.

Avoid exposure to water or high humidity to prevent swelling and warping. MDF is best used in indoor applications where it’s protected from moisture.

Seal Edges

Seal all edges and surfaces, especially if painting, to prevent moisture absorption. Proper sealing also minimizes the release of formaldehyde.

Seal all edges and surfaces, especially if painting, to prevent moisture absorption. Proper sealing also minimizes the release of formaldehyde.

Cleaning

Use a damp cloth to clean MDF surfaces. Avoid using excessive water or harsh chemicals that can damage the board.

Use a damp cloth to clean MDF surfaces. Avoid using excessive water or harsh chemicals that can damage the board.

Environmental Impact

MDF can be eco-friendly if sourced from certified, sustainably managed forests. The use of recycled wood fibers in its production also helps reduce waste. However, the potential release of formaldehyde is a concern. Opting for low-emission or formaldehyde-free MDF products can mitigate this issue.

MDF can be eco-friendly if sourced from certified, sustainably managed forests. The use of recycled wood fibers in its production also helps reduce waste. However, the potential release of formaldehyde is a concern. Opting for low-emission or formaldehyde-free MDF products can mitigate this issue.

MDF vs. Other Materials

MDF vs. Particle Board

Density: MDF is denser and stronger than particle board.

Finish: MDF has a smoother surface, making it better for painting and veneering.

Cost: Particle board is generally cheaper but less durable.

Density: MDF is denser and stronger than particle board.

Finish: MDF has a smoother surface, making it better for painting and veneering.

Cost: Particle board is generally cheaper but less durable.

MDF vs. Plywood

Strength: Plywood is stronger and more resistant to moisture.

Weight: MDF is heavier than plywood.

Surface: MDF has a smoother surface, while plywood has a more natural wood grain appearance.

Strength: Plywood is stronger and more resistant to moisture.

Weight: MDF is heavier than plywood.

Surface: MDF has a smoother surface, while plywood has a more natural wood grain appearance.

MDF vs. Solid Wood

Cost: MDF is more affordable than solid wood.

Machinability: MDF is easier to machine and shape.

Strength: Solid wood offers greater strength and durability.

Cost: MDF is more affordable than solid wood.

Machinability: MDF is easier to machine and shape.

Strength: Solid wood offers greater strength and durability.

Conclusion

Medium Density Fiberboard (MDF) is a versatile, cost-effective, and easy-to-use material that serves a wide range of applications. From furniture making to DIY projects, its smooth surface, uniformity, and affordability make it a popular choice. Understanding its characteristics, applications, and care requirements can help you make the most of this valuable material.

Medium Density Fiberboard (MDF) is a versatile, cost-effective, and easy-to-use material that serves a wide range of applications. From furniture making to DIY projects, its smooth surface, uniformity, and affordability make it a popular choice. Understanding its characteristics, applications, and care requirements can help you make the most of this valuable material.